200L – 220L STEEL DRUMS: The COMPREHENSIVE INDUSTRIAL PACKAGING SOLUTION

Steel drums are an integral component of the modern supply chain. More than just containers, they are strategic packaging assets engineered to optimize logistics efficiency,ensure product integrity, and enhance brand visibility in the global marketplace.

TABLE OF CONTENTS

I. An Overview of Steel Drums

A. Steel Drums: Definition and Core Structure

A metal drum (also known as a steel barrel) is an industrial-grade cylindrical container primarily manufactured from high-quality cold-rolled steel that conforms to international standards like JIS G3141. Its core structure consists of:

- Body: Formed from a single steel sheet and secured with an automated electrical resistance weld, ensuring maximum strength and a leak-proof construction.

- Top & Bottom Lids: Stamped into shape and permanently attached to the body using a mechanical double seaming technique, which creates a robust, hermetic seal.

B. The Superior Benefits of Steel Drums for Your Business

Utilizing MMP steel barrels delivers three strategic advantages for your supply chain:

- Optimal Product Protection: With a high-tensile steel structure, our drums offer exceptional resistance to impact and vibration. Optional internal Epoxy-Phenolic linings provide chemical compatibility, preventing corrosion and contamination to safeguard the purity of all contents, from industrial solvents to food-grade products.

- Enhanced Logistics and Efficiency: The standardized design of the 55-gallon (200L) drum facilitates safe and efficient handling, stacking, and storage with mechanized equipment. This optimizes warehouse space and streamlines your entire supply chain operation.

- Effective Brand Promotion: A steel drum’s smooth surface is an ideal canvas for custom paint colors and high-resolution logo printing. Each unit becomes a mobile billboard, effectively increasing your brand recognition as it travels through the market.

C. Key Industrial Applications

Thanks to their durability and versatility, metal drums are the trusted packaging solution across many demanding industries:

- Chemicals & Petrochemicals: For secure bulk transport of liquid chemicals and reagents.

- Lubricants & Petroleum: For clean containment of industrial oils, greases, and petroleum products.

- Paints, Inks & Solvents: To reliably prevent leakage and solvent evaporation.

- Food & Beverage: (With food-grade linings) For safely storing concentrated juices, cooking oils, and additives.

- Adhesives & Construction: For handling viscous materials like industrial adhesives, rubber, and asphalt.

II. Types of Steel Drums

The correct drum selection depends primarily on the physical properties of the product to be contained (e.g., liquid, solid, or viscous) and the specific requirements of your filling and dispensing processes. Steel drums are broadly classified into two main designs: tight-head and open-head.

A. Tight-Head (Closed-Head) Drums

A tight-head barrel features a non-removable, permanently sealed top lid. It has two small, threaded openings known as bung holes that are used for filling, dispensing, and ventilation.

- Core Advantage: This seamless construction provides a superior, hermetic seal, offering maximum protection against leaks, evaporation, and external contamination. It also ensures a high level of tamper-evidence.

- Best Suited For: The secure transport and storage of low-viscosity liquids.

- Typical Applications:

- Fuels and petroleum products.

- Industrial chemicals and solvents.

- Lubricating oils and greases.

- Liquid food products like juices and flavorings.

For detailed technical specifications, learn more about our tight-head steel drums here.

B. Open-Head Drums

An open-head steel drum features a fully removable lid that is securely fastened to the drum body with a locking ring.

- Core Advantage: The primary benefit is exceptional versatility and accessibility, allowing for easy filling and dispensing of a wide range of materials.

- Best Suited For:

- Solids: Powdered or granular products.

- Viscous Materials: High-viscosity substances such as greases, adhesives, thick paints, and concentrated food pastes.

- Popular Locking Ring Types:

- Lever-Lock: Offers quick and convenient opening and closing.

- Bolt Ring: Provides a tighter seal, enhancing security and tamper resistance, particularly important for businesses operating within Ho Chi Minh City’s diverse industrial landscape.

- Typical Applications:

- Industrial greases.

- Semi-solid food products (butter, jams, concentrated pastes relevant to Vietnam’s food processing sector).

- Powdered chemicals and adhesives.

- Rubber compounds.

For detailed technical specifications relevant to your operations in Ho Chi Minh City, explore our open-head drums here.

C. Specialized Design Variation: Neck-in Drums

This is an innovative modification on the standard drum design, applicable to both tight-head and open-head styles. The top and bottom of the drum are slightly “necked-in,” meaning the diameter of the ends is smaller than the diameter of the main body.

Core Advantage: This design innovation prevents the drums’ rolling hoops from catching on each other when packed tightly. It allows for superior logistics optimization, enabling four drums to fit perfectly onto a standard pallet. This maximizes space utilization within an ISO shipping container, making loading easier and potentially reducing overall freight costs—a significant advantage for businesses managing exports from a busy hub like Ho Chi Minh City.

For technical specifications and to see how this design can improve your shipping efficiency, learn more about our neck-in barrels here.

III. Manufacturing Process & Quality Standards

The quality of every MMP metal drum is engineered. Our automated process and strict Quality Assurance system guarantee each drum offers superior durability, consistency, and full traceability, meeting the highest safety standards.

A. Manufacturing Process

The manufacturing process includes these key stages:

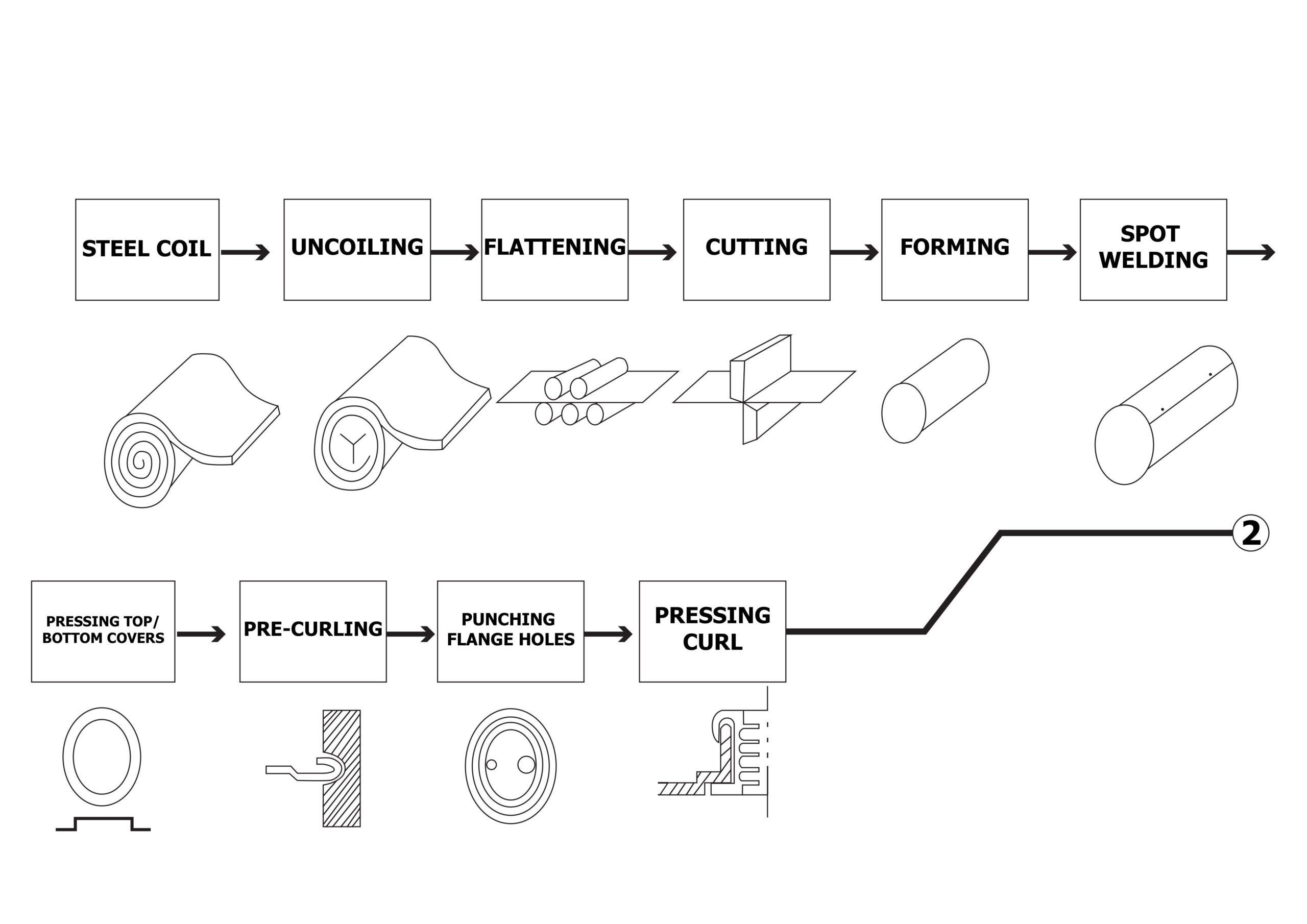

Stage 1: Component Fabrication

Drum Body Manufacturing:

- Uncoiling & Cutting: High-grade cold-rolled steel coils are uncoiled, flattened, and precisely cut to size.

- Forming & Spot Welding: The flat sheets are rolled into perfect cylinders and are spot-welded to temporarily hold their shape for the next stage.

Lid & Bottom Manufacturing:

- Stamping: In parallel, other steel sheets are stamped in high-tonnage presses to form the top and bottom lids.

- Pre-curling & Punching: The outer edge of each lid/bottom is pre-curled for a perfect seam, while bung holes are punched into the top lid as required.

- Bung Opening Formation (Pressing Curl): The metal around the bung holes is then curled and pressed to form a secure, threaded neck.

Stage 2: Body Forming & Final Assembly

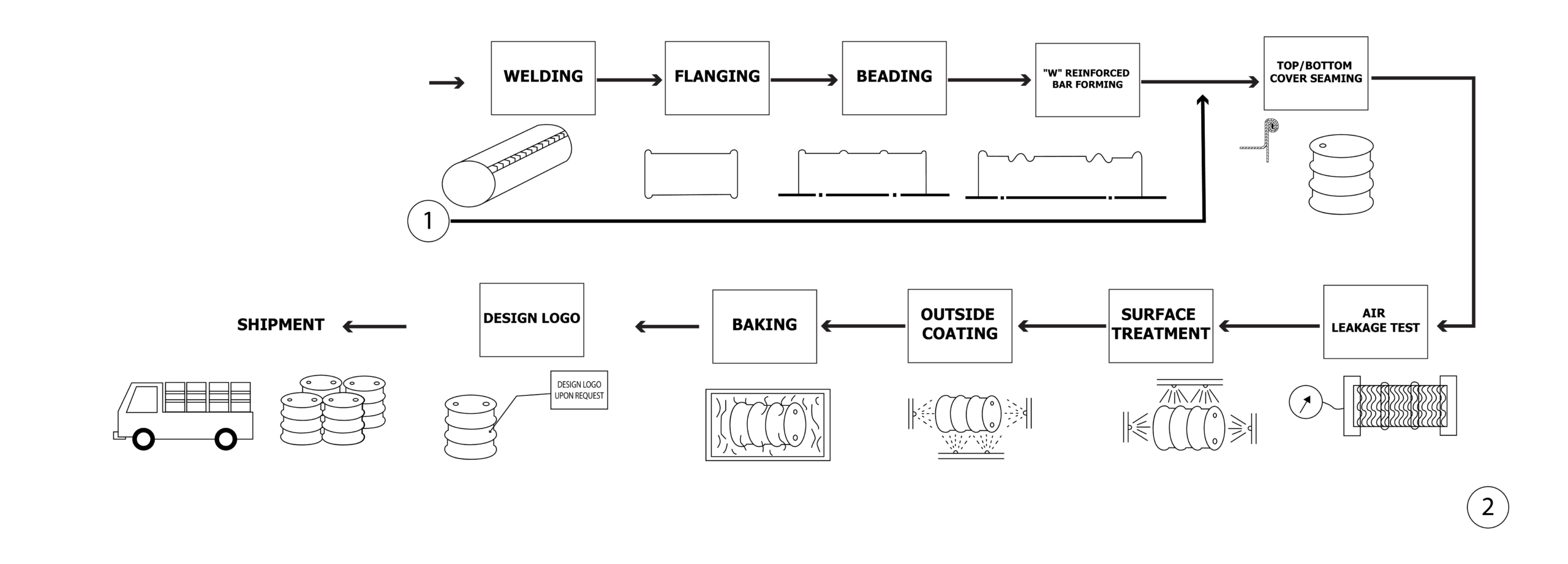

- Seam Welding: The body’s temporary spot weld is replaced by a complete, automated seam weld along its entire length, ensuring a permanent, leak-proof bond.

- Flanging: Both ends of the drum body are flanged outwards to prepare for lid and bottom attachment.

- Beading / Corrugation: Rolling hoops and reinforcing ribs (including “W” profiles) are formed around the body. This beading process adds critical structural integrity for stacking and impact resistance.

- Double Seaming: In the critical final assembly step, the lids and bottom are fitted onto the body. A seaming machine then mechanically interlocks the edges to create a strong, hermetic double seam.

- Leakproofness Testing: Every single barrel produced at our Ho Chi Minh City facility undergoes a pneumatic air leakage test, where it is pressurized and checked for leaks to guarantee a 100% secure seal.

- Surface Preparation: The drum surface is treated (e.g., via shot blasting) to remove impurities and create an ideal surface for paint adhesion.

- Industrial Coating: A uniform layer of high-quality paint is applied according to customer color specifications.

- Curing (Baking): The drums pass through a baking oven to cure the paint, resulting in a hard, durable, and corrosion-resistant finish.

- Final Inspection & Shipment: A final quality control check is performed before the drums are approved for shipment.

B. Steel Gauge (Thickness)

A drum’s steel gauge is the key to balancing durability, cost, and UN-rated safety. We offer tailored options for every need:

- Standard Grade (e.g., 0.8 mm): The cost-effective choice for general cargo and materials in UN Packing Groups II & III.

- Heavy-Duty Grade (e.g., 0.9 mm): For high-value products, demanding transport conditions, or materials in UN Packing Group II.

- Extreme-Duty / UN-Rated (e.g., 1.0 mm+): Mandatory for the most dangerous goods (UN Packing Group I) and high-density products, ensuring full compliance.

C. Interior Linings: The Decisive Factor for Product Compatibility

While the exterior paint protects the drum from the environment, the interior surface is critical for protecting product integrity. The choice between an unlined and a lined drum is based entirely on the chemical compatibility between your product and the steel, a decision crucial for preventing contamination, corrosion, and chemical reactions.

1. Unlined Drums (Bare Steel)

This is a cost-effective option where the interior surface is clean, bare steel.

- Compatibility Principle: Best suited for non-corrosive, non-aqueous products that are “self-preserving” when in direct contact with steel.

- Typical Applications: Petroleum-based products such as:

- Lubricating oils and greases.

- Industrial solvents.

- Oil-based paints and asphalt.

2. Epoxy-Phenolic Lined Drums

A high-performance, thermosetting polymer coating is applied and heat-cured to create a non-reactive, inert barrier between the product and the steel. This lining is mandatory when:

- The product is corrosive to steel (e.g., water-based chemicals, mild acids).

- The product requires absolute purity and must not come into contact with metal.

- Typical Applications:

- Food & Beverage: For products requiring FDA-compliant, food-grade surfaces, crucial for Vietnam’s thriving food export industry (e.g., concentrated fruit juices, cooking oils, food additives).

- Sensitive Chemicals: Pharmaceuticals, fragrances, and high-purity chemicals that cannot tolerate contamination.

- Water-Based Products: Water-based paints, detergents, and various agricultural chemicals.

Important Note: For new or complex chemical formulations, we strongly recommend a product compatibility test before placing a bulk order. Our Ho Chi Minh City-based team can advise on this process to ensure your choice of lining is both safe and optimal for your operations.

D. Our Commitment to Quality: International Certifications & Standards

At MMP, quality is not just an internal metric; it is a commitment validated by respected international standards. Our quality framework is built on two core pillars: Product Safety, certified by the UN, and Process Excellence, assured by ISO 9001.

1. UN Certification: Ensuring Safety in Dangerous Goods Transport

The UN Mark (UN Mark) is the mandatory global standard for packaging used to transport (Dangerous Goods). For businesses in Ho Chi Minh City, this certification is essential for ensuring compliance with international shipping regulations like IMDG Code (for sea freight) and IATA DGR (for air freight).

- Verified Capability: A drum bearing a UN marking (e.g., UN 1A1/Y1.4/200) has passed a series of rigorous performance tests (drop, pressure, leakproofness, stacking). This code certifies the drum’s capability to safely contain materials of a specific Packing Group, corresponding to their hazard level.

- Benefit to Our Clients: Using MMP’s UN-rated drums allows your business to achieve legal compliance, mitigate supply chain risks, and access global markets safely and legitimately.

2. ISO 9001 Standard: The Foundation of a Reliable Manufacturing Process

ISO 9001 is the international standard for a Quality Management System (QMS). Instead of only inspecting the final product, we control and standardize the entire process that creates it.

- Standardized Processes: Our adherence to ISO 9001 ensures consistency and full traceability for every production batch. This system fosters a culture of continuous improvement and risk-based thinking throughout our operations.

- Benefit to Our Clients: MMP clients can be confident that every drum they receive is the result of a stable, controlled, and reliable process. This provides peace of mind and predictable performance for your operations, which is critical in the competitive landscape of July 2025.

IV. A Guide to Selecting and Safely Operating Steel Drums

Selecting and using the correct steel barrel is a technical process that directly impacts supply chain safety and product quality. The following guide will help you make an informed purchasing decision and implement safe operational procedures, which are critical for maintaining high standards in the competitive Ho Chi Minh City market of July 2025.

A. The Optimal Drum Selection Process

1. Analyze Product Requirements (Consult the Safety Data Sheet – SDS):

The most critical source of information is your product’s Safety Data Sheet (SDS). Consulting it will determine:

- Compatibility: Does the product corrode steel or require absolute purity? -> This decides between an unlined (bare steel) or an Epoxy-lined drum.

- Hazard Level: Is the product classified as a Dangerous Good? -> This determines the need for UN Certification and the corresponding Packing Group (I, II, or III).

2. Determine Technical Specifications:

- Lid Type (Open/Tight-Head): Based on the product’s physical state (liquid, solid, viscosity).

- Steel Gauge (Thickness): Based on the product’s specific gravity, transport conditions, and stacking requirements. High-density products or harsh transit demand a thicker gauge.

- Customization: Choose colors for product segregation and add your logo for brand recognition.

B. Best Practices for Safe Operation

Once you have selected the appropriate drum, adhering to the following safety protocols is mandatory to protect personnel and assets:

- Handling & PPE: Always inspect drums for damage before use. Only move drums with proper mechanical equipment (e.g., drum lifters), never by hand-rolling. Ensure personnel are equipped with appropriate Personal Protective Equipment (PPE).

- Static Control (Grounding & Bonding): It is mandatory to properly ground and bond drums when dispensing flammable liquids to prevent static discharge and potential explosions.

- Storage & Labeling: Stack drums only on stable, flat pallets. If storing outdoors, ensure they are properly covered. Always apply clear hazard labels compliant with the Globally Harmonized System (GHS).

V. MMP: Your Trusted Partner for Industrial Packaging Solutions

At MMP, we don’t just sell metal packaging; we deliver peace of mind. We position ourselves as a strategic partner in your supply chain, providing packaging solutions engineered to protect your products, mitigate risks, and enhance your operational efficiency.

A. Our Capabilities & Commitment

Our experience and dedication are demonstrated through three core value pillars:

- Expert Consultation: Through our consultative approach, we help you select the optimal drum specifications (gauge, lining, UN rating) based on your product’s Safety Data Sheet (SDS), ensuring perfect compatibility and absolute safety.

- International-Standard Quality: Our ISO 9001 certified manufacturing process guarantees that every drum leaving our facility is consistent, reliable, and meets the most stringent quality standards.

- Flexible, Customer-Centric Service: We provide a seamless experience from start to finish, quickly responding to custom requirements for color and branding, backed by responsive technical support.

B. Contact Us for a Consultation and Quote

Let MMP’s experts help you analyze your needs and engineer a steel drum solution that not only meets technical requirements but also optimizes your total cost of ownership. In the competitive market of July 2025, a reliable packaging partner is a key advantage. Contact us today to get started!

- Address: 379 Ho Nai 3 Industrial Cluster, Trang Bom District, Dong Nai Province

- Phone:

- 0981 300 860 (Mr. Duong)

- 0961 678 374 (Ms. My)

- Email: dustinnguyen.mmp@gmail.com

- Website: mmp.net.vn